Application of PFA material in semiconductor liquid delivery system

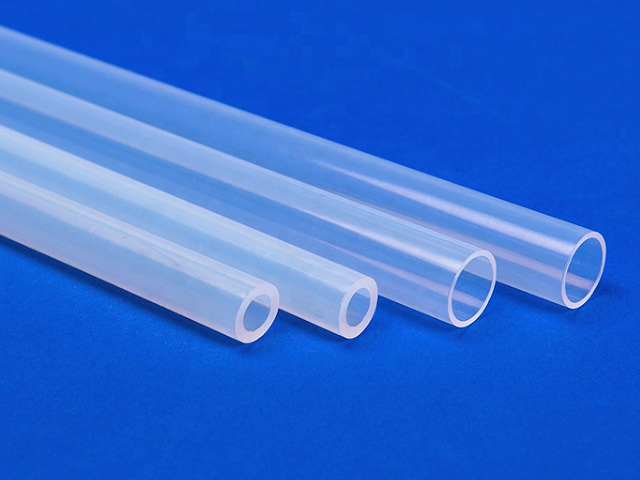

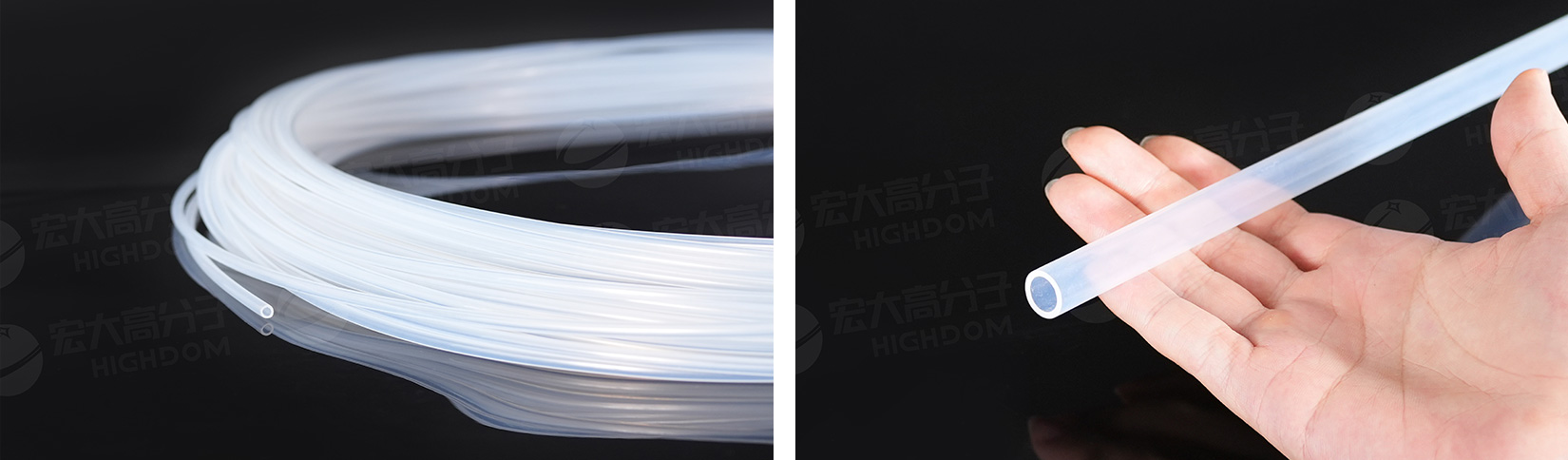

The semiconductor industry has very strict requirements for materials, especially in liquid transportation systems, which require materials to have high corrosion resistance, high temperature resistance, and purity. PFA tube, as a high-performance fluoroplastic, has become an ideal choice for semiconductor liquid delivery systems due to its excellent chemical stability and electrical properties.

The semiconductor industry has very strict requirements for materials, especially in liquid transportation systems, which require materials to have high corrosion resistance, high temperature resistance, and purity. PFA tube, as a high-performance fluoroplastic, has become an ideal choice for semiconductor liquid delivery systems due to its excellent chemical stability and electrical properties.

Semiconductor manufacturing requires purity levels of ppb or even ppt for ultra pure chemicals (UPW, UHP Chemicals) and process environments, and any minor pollution may lead to a decrease in chip yield.

PFA High purity tubes are the preferred choice for the following process steps:

Ultra pure chemical transportation:

Etching solution: Transporting highly corrosive liquids such as hydrofluoric acid, sulfuric acid, nitric acid, phosphoric acid, buffer oxide etching solution, etc.

Cleaning solution: Transport SC1, SC2, RCA cleaning solution, sulfuric acid/hydrogen peroxide mixture, ozone water, etc.

photoresist related chemicals: developer, stripping solution, diluent, etc.

CMP slurry: used to transport grinding fluid for chemical mechanical polishing.

High purity solvents: IPA, acetone, NMP, etc.

Ultra pure water transportation:

transports UPW during final cleaning, wafer rinsing, and other processes.

Process gas transportation: Transport high-purity process gases (inert gases, reaction gases, etc.), especially in areas that require high cleanliness and corrosion resistance.

Chemical mechanical grinding system: grinding fluid supply pipeline, cleaning water pipeline after grinding Wet process equipment: Wet etching table, fluid pipelines inside the cleaning machine, spray pipes, immersion tank circulation pipelines, etc.

Analysis sampling system: Connect the sampling pipeline of the online chemical concentration monitor, requiring no pollution and low adsorption. As a professional manufacturer of fluoroplastics, Zhuzhou Hongda has a thousand level semiconductor dust-free workshop, introduces internationally advanced PFA tube extrusion equipment, uses genuine PFA raw materials from Daikin and Kemu, has a high-precision temperature control system and stable extrusion speed, which can ensure the performance stability and dimensional accuracy of PFA tubes during the extrusion process. It has passed SEMI-57 certification and provides high-quality PFA products for the semiconductor industry, helping the stable development of the semiconductor industry and domestic substitution.

Semiconductor manufacturing requires purity levels of ppb or even ppt for ultra pure chemicals (UPW, UHP Chemicals) and process environments, and any minor pollution may lead to a decrease in chip yield.

PFA High purity tubes are the preferred choice for the following process steps:

Ultra pure chemical transportation:

Etching solution: Transporting highly corrosive liquids such as hydrofluoric acid, sulfuric acid, nitric acid, phosphoric acid, buffer oxide etching solution, etc.

Cleaning solution: Transport SC1, SC2, RCA cleaning solution, sulfuric acid/hydrogen peroxide mixture, ozone water, etc.

photoresist related chemicals: developer, stripping solution, diluent, etc.

CMP slurry: used to transport grinding fluid for chemical mechanical polishing.

High purity solvents: IPA, acetone, NMP, etc.

Ultra pure water transportation:

transports UPW during final cleaning, wafer rinsing, and other processes.

Process gas transportation: Transport high-purity process gases (inert gases, reaction gases, etc.), especially in areas that require high cleanliness and corrosion resistance.

Chemical mechanical grinding system: grinding fluid supply pipeline, cleaning water pipeline after grinding Wet process equipment: Wet etching table, fluid pipelines inside the cleaning machine, spray pipes, immersion tank circulation pipelines, etc.

Analysis sampling system: Connect the sampling pipeline of the online chemical concentration monitor, requiring no pollution and low adsorption. As a professional manufacturer of fluoroplastics, Zhuzhou Hongda has a thousand level semiconductor dust-free workshop, introduces internationally advanced PFA tube extrusion equipment, uses genuine PFA raw materials from Daikin and Kemu, has a high-precision temperature control system and stable extrusion speed, which can ensure the performance stability and dimensional accuracy of PFA tubes during the extrusion process. It has passed SEMI-57 certification and provides high-quality PFA products for the semiconductor industry, helping the stable development of the semiconductor industry and domestic substitution.

中文

中文

EN

EN