Application of PVDF board in chemical fluids (high-performance anti-corrosion solution)

In highly corrosive environments such as chemical, semiconductor, and electroplating, the long-term stability and safety of storage tanks and containers directly determine production efficiency and operating costs. Polyvinylidene fluoride (PVDF), as a high-performance fluoroplastic, has become a key material for chemical anti-corrosion equipment due to its excellent corrosion resistance, mechanical strength, and thermal stability. Especially when it is used as the lining of fiberglass reinforced plastic (FRP) storage tanks in the form of sheet metal, it not only solves the pain points of traditional metal tanks being prone to corrosion and bulky, but also achieves a good effect of "dual material composite and doubled performance".

In highly corrosive environments such as chemical, semiconductor, and electroplating, the long-term stability and safety of storage tanks and containers directly determine production efficiency and operating costs. Polyvinylidene fluoride (PVDF), as a high-performance fluoroplastic, has become a key material for chemical anti-corrosion equipment due to its excellent corrosion resistance, mechanical strength, and thermal stability. Especially when it is used as the lining of fiberglass reinforced plastic (FRP) storage tanks in the form of sheet metal, it not only solves the pain points of traditional metal tanks being prone to corrosion and bulky, but also achieves a good effect of "dual material composite and doubled performance". With the continuous development of the chemical industry, the performance requirements for storage tank materials are also increasing. PVDF fiberglass backing plate, as a high-performance composite material, has been widely used in the field of chemical storage tanks due to its excellent corrosion resistance, high temperature resistance, and high mechanical strength. The application of PVDF fiberglass backing plate in chemical storage tanks not only effectively solves the problems of corrosion and short service life of traditional materials, but also brings significant economic and environmental benefits to the chemical industry. With the continuous advancement of material technology and the accumulation of application experience, the application prospects of PVDF fiberglass backing plate in the field of chemical storage tanks will be even broader.

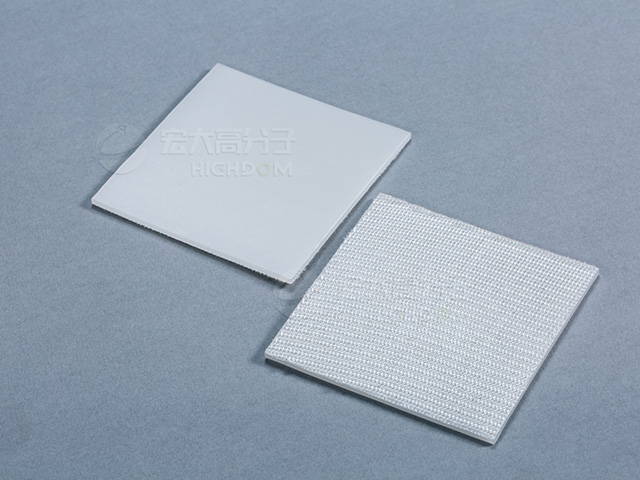

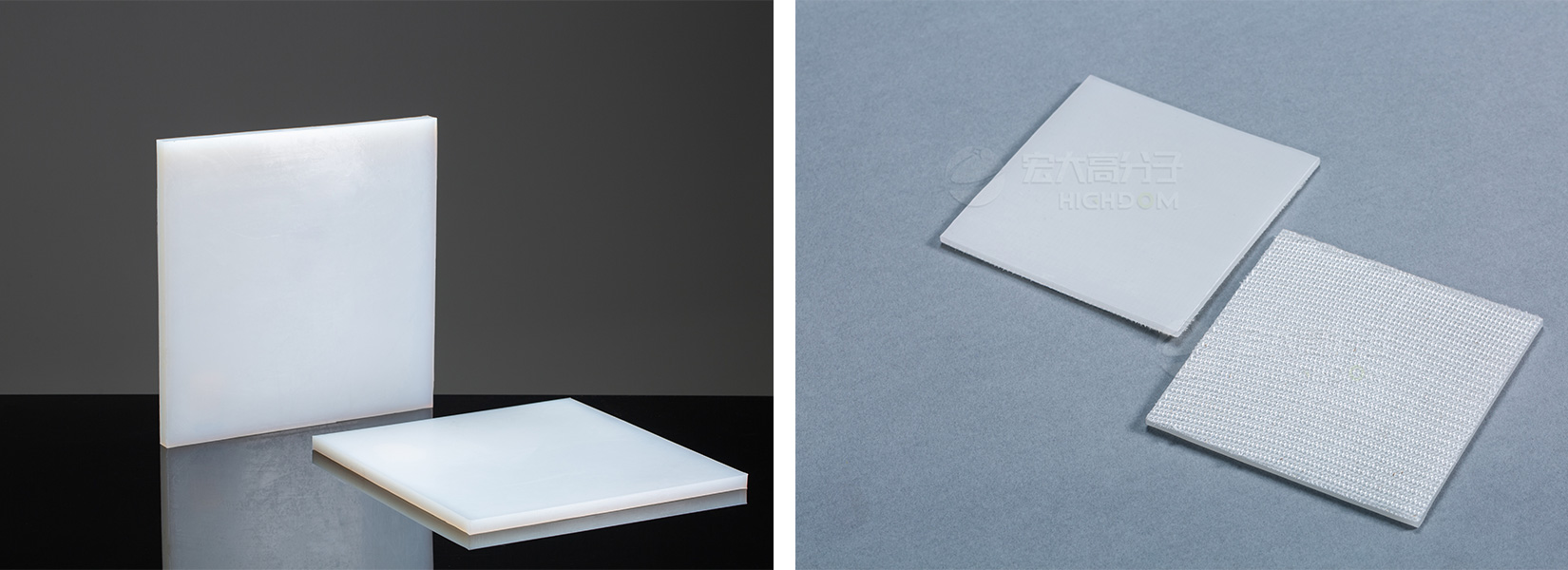

The PVDF backing plate provided by our company is commonly used with a thickness of 2-5mm and a width of 1500mm. It is extruded from branded raw materials and has stable performance and high product reliability. It can operate stably under agreed working conditions and has helped multiple customers successfully replace imported products. It is also exported to overseas markets and widely used as lining material for various chemical storage tanks and FRP storage tanks. (Other optional materials include PFA and PTFE)

Case 1: Sewage treatment equipment

Sewage treatment equipment is often exposed to high concentrations of acids, bases, and organic solvents. The strong corrosion resistance of PVDF plates makes them a key material for constructing these equipment. In a large sewage treatment plant, PVDF sheets are used to manufacture the lining of sewage reaction tanks. In such extreme environments, PVDF plates not only effectively resist the erosion of corrosive media, but also maintain good structural stability, with a service life exceeding expectations, reducing maintenance frequency and costs. Case 2: Chemical Reactor In the petrochemical production process, chemical reactors need to withstand high temperatures, high pressures, and highly corrosive chemical media. PVDF plates are widely used in the manufacturing of chemical reactor liners and components due to their ability to maintain stability in extreme environments. A chemical production enterprise uses PVDF plates to manufacture chemical reactors, which not only improves the corrosion resistance of the equipment, but also maintains good mechanical strength under high temperature and pressure, ensuring the stability and safety of the production process.

Application advantages summary

Improving the service life of storage tanks: Excellent corrosion resistance effectively extends the service life of storage tanks and reduces the frequency of replacement and maintenance.

Ensure storage quality: The high cleanliness and chemical inertness of the material ensure that the quality of the storage medium is not affected.

Reduced operating costs: Reduced material loss and maintenance costs caused by corrosion, lowering overall operating costs.

Improving safety: The stability and high strength of the material enhance the safety of tank operation. If you have any questions about fluoroplastic lining materials or would like to obtain more product information, please feel free to contact our company at any time.

The PVDF backing plate provided by our company is commonly used with a thickness of 2-5mm and a width of 1500mm. It is extruded from branded raw materials and has stable performance and high product reliability. It can operate stably under agreed working conditions and has helped multiple customers successfully replace imported products. It is also exported to overseas markets and widely used as lining material for various chemical storage tanks and FRP storage tanks. (Other optional materials include PFA and PTFE)

Case 1: Sewage treatment equipment

Sewage treatment equipment is often exposed to high concentrations of acids, bases, and organic solvents. The strong corrosion resistance of PVDF plates makes them a key material for constructing these equipment. In a large sewage treatment plant, PVDF sheets are used to manufacture the lining of sewage reaction tanks. In such extreme environments, PVDF plates not only effectively resist the erosion of corrosive media, but also maintain good structural stability, with a service life exceeding expectations, reducing maintenance frequency and costs. Case 2: Chemical Reactor In the petrochemical production process, chemical reactors need to withstand high temperatures, high pressures, and highly corrosive chemical media. PVDF plates are widely used in the manufacturing of chemical reactor liners and components due to their ability to maintain stability in extreme environments. A chemical production enterprise uses PVDF plates to manufacture chemical reactors, which not only improves the corrosion resistance of the equipment, but also maintains good mechanical strength under high temperature and pressure, ensuring the stability and safety of the production process.

Application advantages summary

Improving the service life of storage tanks: Excellent corrosion resistance effectively extends the service life of storage tanks and reduces the frequency of replacement and maintenance.

Ensure storage quality: The high cleanliness and chemical inertness of the material ensure that the quality of the storage medium is not affected.

Reduced operating costs: Reduced material loss and maintenance costs caused by corrosion, lowering overall operating costs.

Improving safety: The stability and high strength of the material enhance the safety of tank operation. If you have any questions about fluoroplastic lining materials or would like to obtain more product information, please feel free to contact our company at any time.

中文

中文

EN

EN